How-To: Differential Removal

#1

Rear Differential Removal

***Scroll farther down for front***

Well, my rear differential was leaking so I figured I'd take some pics along the way to help others out who maybe aren't too sure on the process. I'm pretty sure this is in order, but if not sorry, I didn't follow a book and just took it apart as I saw fit. Please be aware that if you follow these instructions you do so at your own risk and I take no responsibility. Use jackstands and be careful; you can seriously hurt yourself.

Step 1: Loosen all your lugnuts and remove your wheels!

Step 2: Remove two bolts holding caliper to caliper bracket. Slide caliper off and remove brake pads. Do not disconnect brakeline. Just hang caliper out of the way. I stuck it on one of the loops of my springs.

Step 3: Remove two 12-point bolts holding caliper bracket to hub.

Step 4: Step Removed

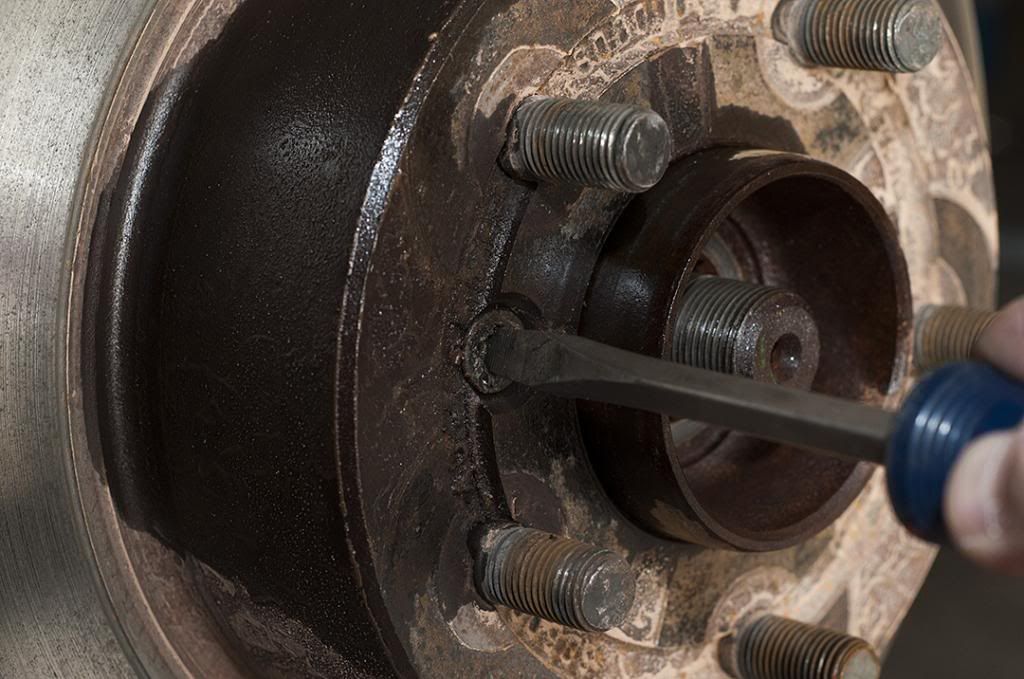

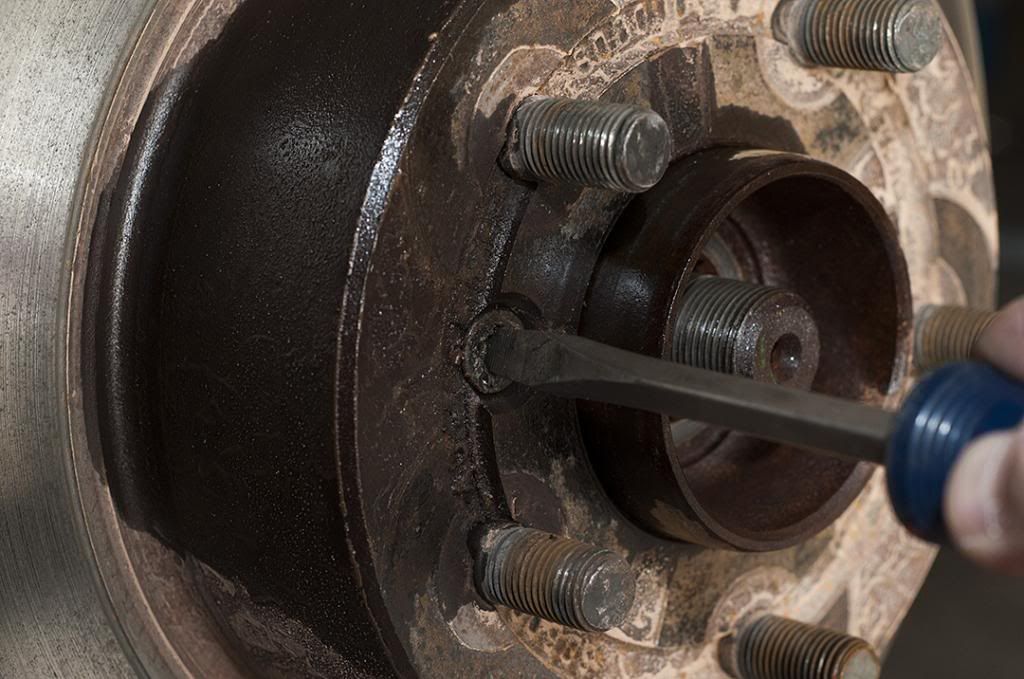

Step 5: Remove brake rotor retaining spring. I had to drill the other side out. I did not replace these as the wheel keeps the rotor on. Remove your rotor. I ended up removing the dust shield; held on by 3 bolts. I had to coax the rotor off with a rubber mallet. Do not use anything metal to pound off your rotor as it will cause damage to the rotor face.

Step 6: Remove the wheel speed sensor retaining bolt with an allen wrench and pull out your wheel speed sensor. This may not be necessary, but I didn't want to risk it getting damaged.

Step 7: Disconnect your wheel speed sensor connector from the vehicle wiring. The connector is located on the frame rail in two retaining clips.

Step 8: Remove 4 bolts from the back of the wheel hub. There are two in the front of the axle and two behind it.

Step 9: Pull your axle and hub out. If you plan on using the same o-ring seal when you reassemble be careful prying too close to the center of your hub as the o-ring sits here and may be damaged. Notice mine was WAY overdue for a rear fluid change.

Step 10: Do the same as above to the other side of the vehicle.

Step 11: Remove all the bolts holding the biscuit on your vehicle. 6 total. 3 are removed in this picture already. Once this is done you can push on the driveshaft towards the front of the vehicle and it will telescope in to give clearance. Once you pull it away from the rear differential you can mark the the front portion and rear portion and just pull it apart. It's way faster than trying to remove the 4 bolts connecting the driveshaft to your parking brake.

Step 11b: Inspect the input of your differential for leaks. If you see marks from fluid here; this will be a good time to replace this seal. There are instructions in the RAVE.

Step 12: Remove the nut and washer from the side bracket of your differential and remove the cable.

Step 13: Drain your differential. It's the bolt on the bottom left of the housing in the picture below. You need to use a 1/2" wratchet or breaker bar to remove it. Remove all bolts attaching the differential assembly to the axle housing.

Step 14: Brake the bond of sealant and pull the differential out. You may get hung up on your sway bar endlink, but it will clear it.

Step 15: Inspect your differential assembly. Turn your input shaft and inspect all the teeth on your pinion gear (the large outer one) and the input gear. You want to check for any broken/missing teeth or excessive wear. The gears should be flat on top and have a nice edge that is not too over rounded. Also inspect your spider gears on the inside of your center differential section. Also check for any binding or grinding as you turn it. This could be an indication your bearings are bad.

Step 16: If you have an air compressor, blow our your vent tube to make sure it is not clogged. Then, if all checks out, reassemble sealing appropriate sealant in reverse order.

I'll post pictures of a bad differential tomorrow when I remove the front one. It had tons of metal shavings on the drain plug.

***Scroll farther down for front***

Well, my rear differential was leaking so I figured I'd take some pics along the way to help others out who maybe aren't too sure on the process. I'm pretty sure this is in order, but if not sorry, I didn't follow a book and just took it apart as I saw fit. Please be aware that if you follow these instructions you do so at your own risk and I take no responsibility. Use jackstands and be careful; you can seriously hurt yourself.

Step 1: Loosen all your lugnuts and remove your wheels!

Step 2: Remove two bolts holding caliper to caliper bracket. Slide caliper off and remove brake pads. Do not disconnect brakeline. Just hang caliper out of the way. I stuck it on one of the loops of my springs.

Step 3: Remove two 12-point bolts holding caliper bracket to hub.

Step 4: Step Removed

Step 5: Remove brake rotor retaining spring. I had to drill the other side out. I did not replace these as the wheel keeps the rotor on. Remove your rotor. I ended up removing the dust shield; held on by 3 bolts. I had to coax the rotor off with a rubber mallet. Do not use anything metal to pound off your rotor as it will cause damage to the rotor face.

Step 6: Remove the wheel speed sensor retaining bolt with an allen wrench and pull out your wheel speed sensor. This may not be necessary, but I didn't want to risk it getting damaged.

Step 7: Disconnect your wheel speed sensor connector from the vehicle wiring. The connector is located on the frame rail in two retaining clips.

Step 8: Remove 4 bolts from the back of the wheel hub. There are two in the front of the axle and two behind it.

Step 9: Pull your axle and hub out. If you plan on using the same o-ring seal when you reassemble be careful prying too close to the center of your hub as the o-ring sits here and may be damaged. Notice mine was WAY overdue for a rear fluid change.

Step 10: Do the same as above to the other side of the vehicle.

Step 11: Remove all the bolts holding the biscuit on your vehicle. 6 total. 3 are removed in this picture already. Once this is done you can push on the driveshaft towards the front of the vehicle and it will telescope in to give clearance. Once you pull it away from the rear differential you can mark the the front portion and rear portion and just pull it apart. It's way faster than trying to remove the 4 bolts connecting the driveshaft to your parking brake.

Step 11b: Inspect the input of your differential for leaks. If you see marks from fluid here; this will be a good time to replace this seal. There are instructions in the RAVE.

Step 12: Remove the nut and washer from the side bracket of your differential and remove the cable.

Step 13: Drain your differential. It's the bolt on the bottom left of the housing in the picture below. You need to use a 1/2" wratchet or breaker bar to remove it. Remove all bolts attaching the differential assembly to the axle housing.

Step 14: Brake the bond of sealant and pull the differential out. You may get hung up on your sway bar endlink, but it will clear it.

Step 15: Inspect your differential assembly. Turn your input shaft and inspect all the teeth on your pinion gear (the large outer one) and the input gear. You want to check for any broken/missing teeth or excessive wear. The gears should be flat on top and have a nice edge that is not too over rounded. Also inspect your spider gears on the inside of your center differential section. Also check for any binding or grinding as you turn it. This could be an indication your bearings are bad.

Step 16: If you have an air compressor, blow our your vent tube to make sure it is not clogged. Then, if all checks out, reassemble sealing appropriate sealant in reverse order.

I'll post pictures of a bad differential tomorrow when I remove the front one. It had tons of metal shavings on the drain plug.

Last edited by BrandonS; 01-06-2013 at 10:21 PM.

The following users liked this post:

Clay99d2 (08-28-2016)

#4

Do you always use air tools to take lug nuts off? The lug nuts are not supposed to be that tight

I think you run a big risk using that tool on this truck so that is my only complaint.

If your intention was to make this task easier on someone i think you succeeded. Great job!

I think you run a big risk using that tool on this truck so that is my only complaint.

If your intention was to make this task easier on someone i think you succeeded. Great job!

Last edited by lr2001silver; 11-18-2012 at 09:59 AM.

#6

Front Differential Removal

Step #1: Place a drain pan under differential and remove the lower drain plug using a 1/2" wratchet or breaker bar. While waiting for it to drain remove your lugnuts and remove the wheel.

Step #2: Remove two bolts holding caliper onto bracket. Pull caliper back from bracket and once free hang out of the way. I hung mine on the suspension beam that runs from the rear of the vehicle forward. Remove brake pads from caliper bracket and set aside.

Step #3: Remove two 12-point bolts holding caliper bracket onto hub. Remove caliper bracket and set aside.

Step #4: Remove your rotor retaining screw. I ended up drilling this out on 3 out of 4 rotors on my vehicle. If your rotor looks like this you should get a new one. My caliper is frozen up a bit I believe. Leave the axle retaining nut (the big one) on unless you need to seperate your axle from the hub.

Step #5: Remove your wheel speed sensor retaining bolt with an allen wrench. Set the screw aside and remove the sensor from the hub and leave hang for now.

Step #6: Remove four bolts securing hub to axle. There are two front and two back. To create more room to work with use the steering wheel.

Step #7: Pull the sensor up and out of the way for the cv boot to clear it when removing the axle. Pull on the hub and the axle will come with it. It will be a tight fit, but the boot will clear your sensor and make it through the large hole.

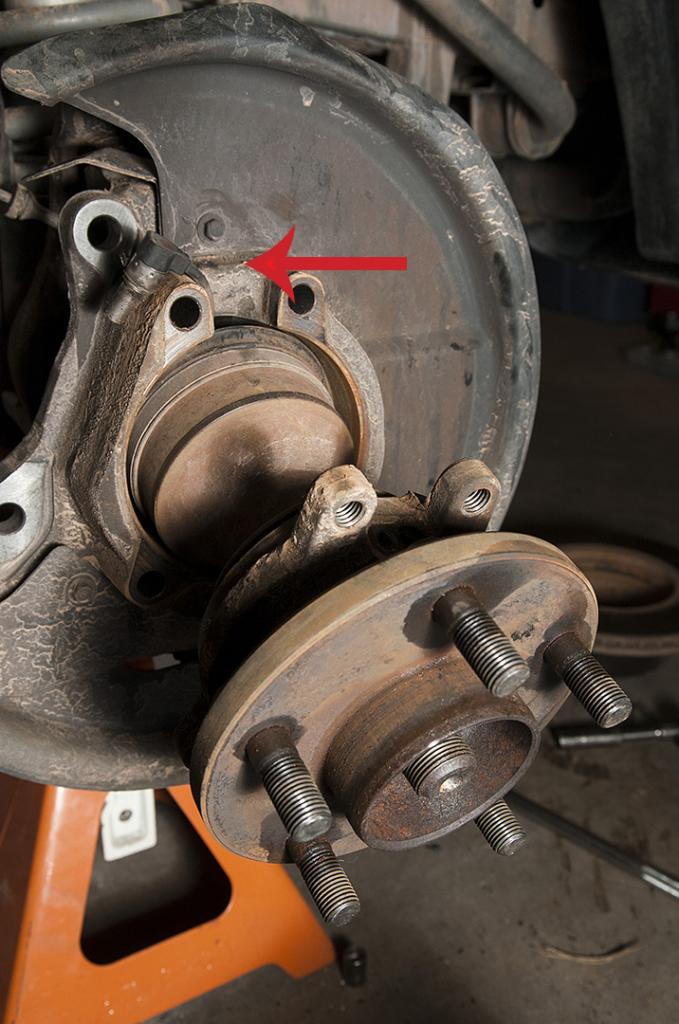

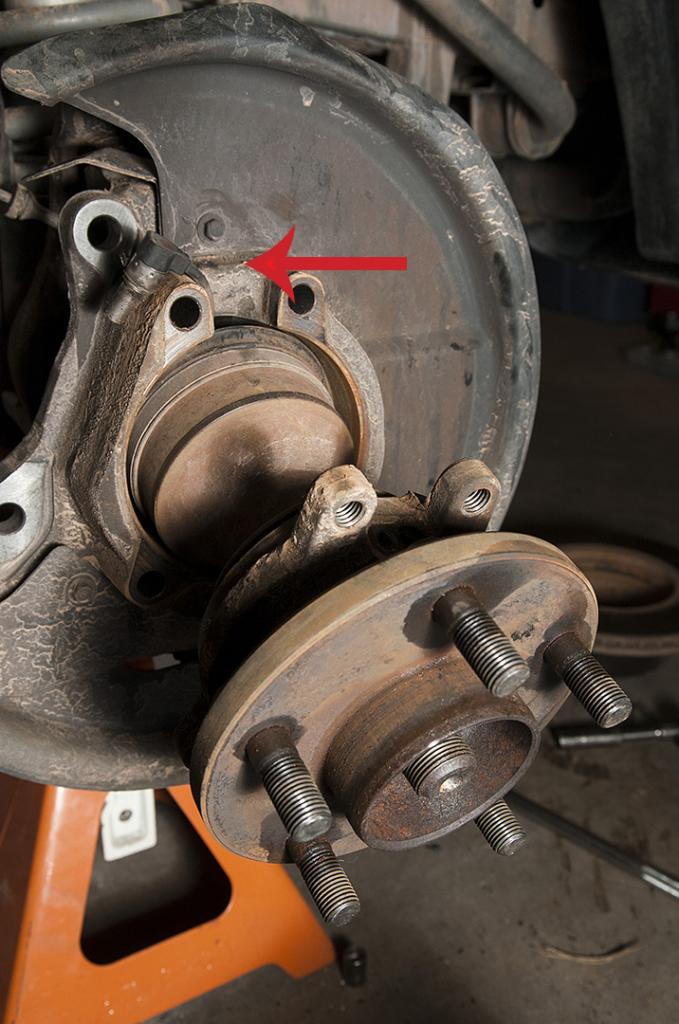

Step #8: Inspect the inside for signs of leakage. If your seal is leaking it will puddle up or create a stain where the arrow in the picture is pointing. If you have signs of a leak, before reassembly replace the axle seal.

Step #9: Climb underneath the vehicle and remove 4 bolts securing your propshaft to the input of your differential. Once removed you can simply swing your propshaft towards the center of the vehicle out of the way. Inspect your differential input area for a leak. In the picture you below you can see mine is leaking from that area.

Step #11: Remove the passenger side nut for the long tie rod bar going from the driver's side to this side. Once removed pop the tie rod out and swing the entire bar over to the driver's side. This needs removed because the differential won't clear it when you go to remove it.

Step #12: Remove all the bolts securing the differential assembly to the axle housing. If you did step #11 before me, you will have the convenience of the bar not being in the way. Once all bolts are removed, break the sealant bond and pull straight out. Be careful as it's slightly heavy.

Step #1: Place a drain pan under differential and remove the lower drain plug using a 1/2" wratchet or breaker bar. While waiting for it to drain remove your lugnuts and remove the wheel.

Step #2: Remove two bolts holding caliper onto bracket. Pull caliper back from bracket and once free hang out of the way. I hung mine on the suspension beam that runs from the rear of the vehicle forward. Remove brake pads from caliper bracket and set aside.

Step #3: Remove two 12-point bolts holding caliper bracket onto hub. Remove caliper bracket and set aside.

Step #4: Remove your rotor retaining screw. I ended up drilling this out on 3 out of 4 rotors on my vehicle. If your rotor looks like this you should get a new one. My caliper is frozen up a bit I believe. Leave the axle retaining nut (the big one) on unless you need to seperate your axle from the hub.

Step #5: Remove your wheel speed sensor retaining bolt with an allen wrench. Set the screw aside and remove the sensor from the hub and leave hang for now.

Step #6: Remove four bolts securing hub to axle. There are two front and two back. To create more room to work with use the steering wheel.

Step #7: Pull the sensor up and out of the way for the cv boot to clear it when removing the axle. Pull on the hub and the axle will come with it. It will be a tight fit, but the boot will clear your sensor and make it through the large hole.

Step #8: Inspect the inside for signs of leakage. If your seal is leaking it will puddle up or create a stain where the arrow in the picture is pointing. If you have signs of a leak, before reassembly replace the axle seal.

Step #9: Climb underneath the vehicle and remove 4 bolts securing your propshaft to the input of your differential. Once removed you can simply swing your propshaft towards the center of the vehicle out of the way. Inspect your differential input area for a leak. In the picture you below you can see mine is leaking from that area.

Step #11: Remove the passenger side nut for the long tie rod bar going from the driver's side to this side. Once removed pop the tie rod out and swing the entire bar over to the driver's side. This needs removed because the differential won't clear it when you go to remove it.

Step #12: Remove all the bolts securing the differential assembly to the axle housing. If you did step #11 before me, you will have the convenience of the bar not being in the way. Once all bolts are removed, break the sealant bond and pull straight out. Be careful as it's slightly heavy.

Last edited by BrandonS; 01-06-2013 at 10:23 PM.

The following users liked this post:

cvhyatt (03-27-2021)

#7

Do you always use air tools to take lug nuts off? The lug nuts are not supposed to be that tight

I think you run a big risk using that tool on this truck so that is my only complaint.

If your intention was to make this task easier on someone i think you succeeded. Great job!

I think you run a big risk using that tool on this truck so that is my only complaint.

If your intention was to make this task easier on someone i think you succeeded. Great job!

#9

D300 w/ SB900 bouncing it off the fender well, concrete, or the other project sitting beside the Rover. There may be one or two with the flash held in my left hand triggered by CLS; not sure if I used those or not. The first set was with my 50mm lens and an SB-600 for the most part because my batteries for the flash were dying. The second set I used my Tamron 17-50 f2.8 and SB-900. It was just a PITA to use the 50 that close. Photography is my secondary hobby to automobiles.

I by no means set up a photoshoot for this. I just grabbed the camera and took pictures.

I by no means set up a photoshoot for this. I just grabbed the camera and took pictures.

Last edited by BrandonS; 11-18-2012 at 09:55 PM.